Laser source from IPG Photonics (USA)

Ytterbium fiber laser consumes 70% less energy than its counterparts. The laser source doesn’t have moving parts or an optical system that needs adjusting and tuning. That is why we can guarantee 100 000 hours of work without maintenance.

Laser head from industry leader HIGHYAG (Germany)

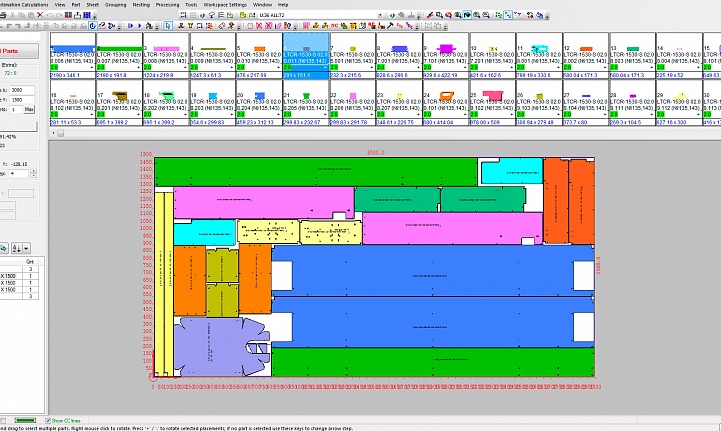

Automatic focal length adjustment

When selecting material from the adjustment library, the focal length is automatically set

Dynamic beam width control

Helps to achieve the best cutting quality on complex contours and increase the speed

The sealed chamber eliminates the ingress of dust onto the optical elements and, unlike the cartridge replacement system of the lens, and increases the life of the head by an order of magnitude

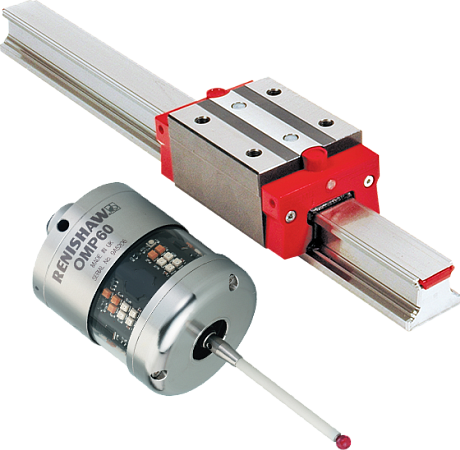

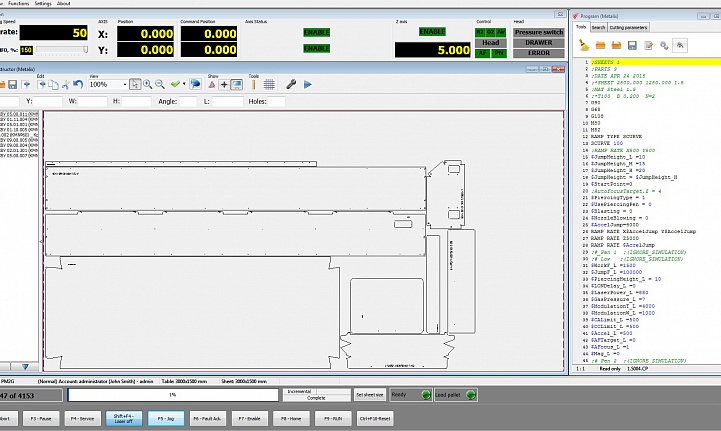

Intelligent control systems

The tracking sensor ensures the stability of the optical head holding with an accuracy of 0.03 mm, which ensures the highest quality of the cut.

The collision protection system will detect the obstacle in time and stop the car until the cause is eliminated.

Sensors for temperature monitoring of the nozzle and contamination of the optics in time signal problems and help prevent metal spoilage.

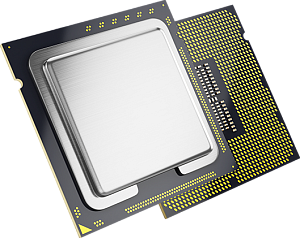

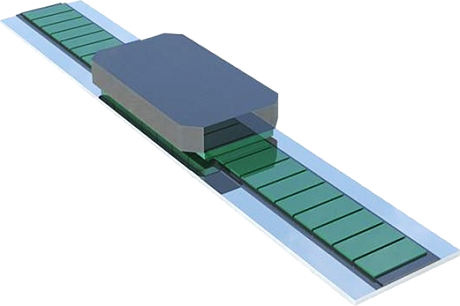

CNC system from AEROTECH (USA)

Used for complex high-speed precision laser cutting machines based on linear motor drives with an exceptional level of accuracy, reliability and efficiency. AEROTECH is the main supplier of CNC systems in NASA

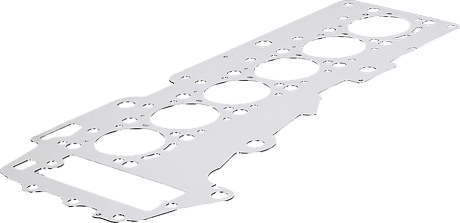

Gas regulation system

Allows you to connect up to 3 different gases simultaneously - air, oxygen and nitrogen. There is no need to manually switch gases, as in the case of single- or dual-channel systems

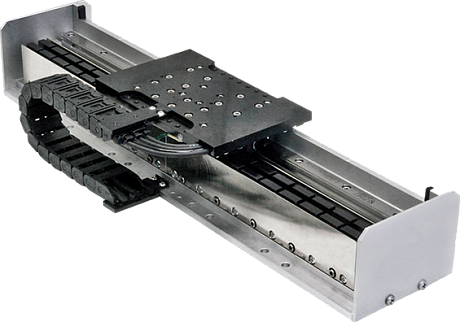

Effective 6-zone extraction system

The extraction system consists of six independent zones operating directly in the processing area, which increases the efficiency of removing combustion products and reduces power consumption.