Software SharpLase Soft TM

Training to work on software

Vector and bitmap formats

for works of any complexity

More than 50 different fonts

with the possibility of unlimited expansion

24 types of linear and two-dimensional barcodes

PDF417, Data Matrix, UPC, EAN and others

Photographic quality

marking images

Operating Systems

Windows 2000, Windows XP, Windows Vista, Windows 7

Marking features

Pictures

Graphics and text

Bar codes

Custom software

Layout module

Efficient cutting modes

Safety

Operator control

Material library

Remote diagnostics

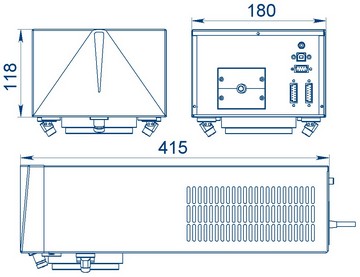

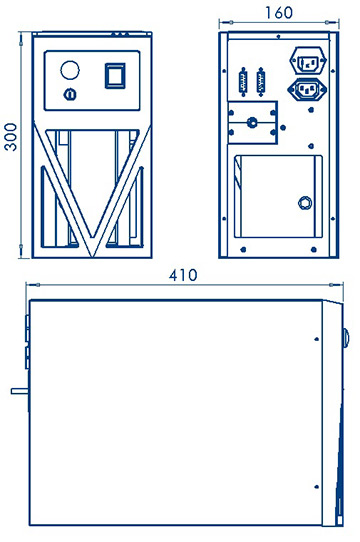

Basic information

- Quick change of marking and engraving settings

- Different marking settings in repeated cycles

- Enables inverted marking of bitmap images

- Marking and engraving on flat and cylindrical surfaces

- Inverting X and Y coordinates

- Marking field linearity adjustment

- Center of the marking field scale and position adjustment

- Mark-on-fly mode

- 3D marking

Basic information

- Photographic quality of marked images

- Three algorithms of level of gray conversion with visual control over the result

- Conversion of monochrome bitmap images into vector for quicker marking and engraving

Basic information

- Basic graphics: lines, splines, sector, ellipse, rectangle, polygon

- Supports all TrueType fonts

- Linear and elliptical text

- Multiline text with aligning capability

- Objects convertion: rotation, scaling, mirroring, grouping

- Shading of objects in a group

- Vector mode for broad line marking

Types of supported files

- Vector files: * .SMF (SharpLase files), * .DXF.

- Bipmap files: * .BMP, * .jpg, * .jpeg.

- 3D files: * .stl.

Basic information

- 24 types of barcodes including 2D codes: PDF417, MaxiCode, DataMatrix

- Direct and inverted codes marking with fields size adjusting capability

- The serial numbers and the barcodes

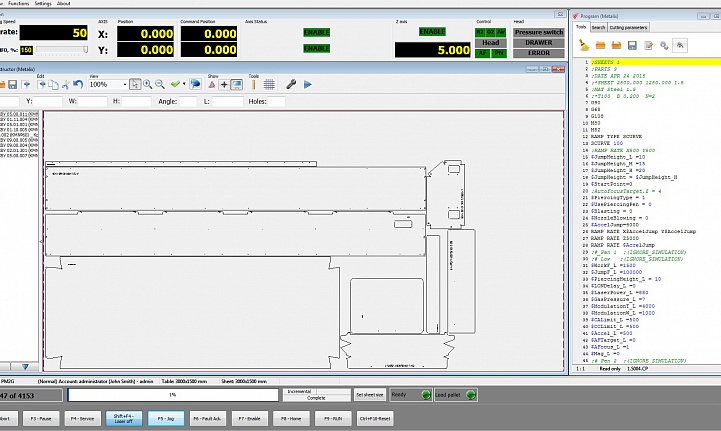

Custom software

We offer our custom software SharpCut® Control. Our solution saves time of the operator on creating templates and typical tasks. Your employees will undergo free training.

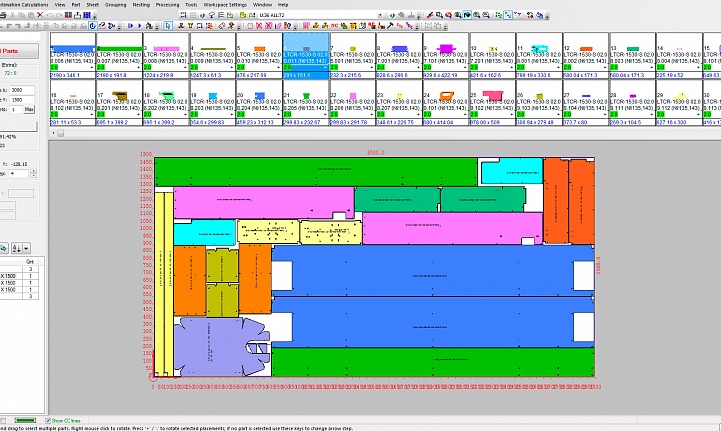

Layout module

The AutoNest module helps to lay out the parts of complex shapes for optimal material use, to set micro jumpers in the cutting contour and to optimize idle running.

Efficient cutting modes

Controlling emission power depending on speed to get quality acute and straight angles. Cross cutting with general cut in automated mode greatly saves time. Impulse mode is for high quality processing of complex contours.

Safety

Installing safety zones - areas with sheet clasps or holders. The function of generating safe runs allows for automated avoidance of areas with parts already cut out that can be raised over the sheet.

Operator control

Software allows for keeping records of billets, done parts and manufacture wastes.

Material library

SharpCut® Control software has a big library of materials, which allows for automated tuning of all parameters of the laser complex.

Remote diagnostics

The feature of remote diagnostics of the machine makes it possible to bring the time of machine stand to a minimum, promptly detect a fault or exclude offsite expenses connected with faulty equipment tuning.